Virtually Test and Understand Systems in Specific Environments Rapidly

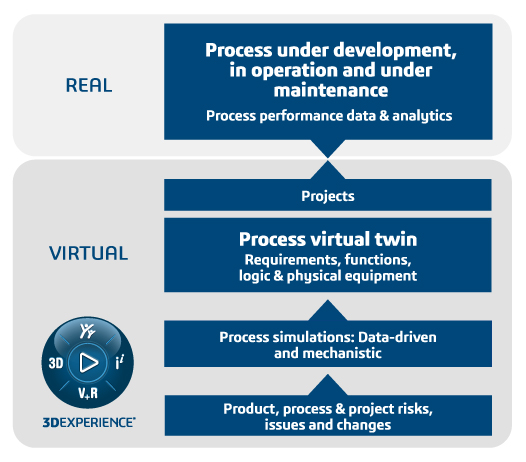

Welcome to the virtual twin experience, where the future of pharmaceutical process development comes to life. Unlike traditional digital twins, our virtual twin transcends boundaries, enabling you to explore the realm of possibilities and shape the future of pharmaceutical manufacturing.

Why Choose a Virtual Twin Experience?

Our virtual twin experience bridges the gap between the virtual and the real, offering unparalleled insights into past experiences to navigate future endeavors. By seamlessly connecting virtual simulations with real-world scenarios, therefore, empowering you to optimize processes, enhance quality, and drive innovation.

Accelerate Process Development and Optimization

With virtual twins, you can accelerate every phase of process development, from initial concept to final production. As a result, seamlessly transition from process development to tech transfer and facility acceptance with precision and efficiency.

Empower Stakeholders Across the Organization

From Therapeutic Area Leadership to Clinical, you can empower stakeholders at every level. In addition, answering critical questions, optimizing processes, and making informed decisions to drive success across the organization.

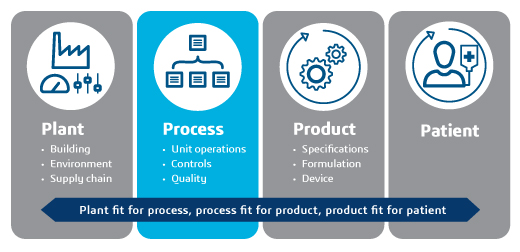

The Path to Predictive Process Development

Embrace predictive modeling and simulation to gain deeper insights into process behavior, risks, and outcomes. Our virtual twins lay the foundation for predictive process development, enabling right-first-time operations and accelerating time to market.

Join the Virtual Twin Experience

In conclusion, by embarking on a journey of innovation and efficiency with our comprehensive virtual twin together, we can unlock the full potential of pharmaceutical process development. Consequently, shaping the future of healthcare. Join us and revolutionize the way we create life-changing therapies.

Realize Your Potential:

- Quality Improvements: Enhance product quality by up to 34%

- Cost Reduction: Reduce manufacturing costs by 30%

- Increased Throughput: Boost throughput by 25%

- Minimized Downtime: Decrease unplanned downtime by 28%