Description

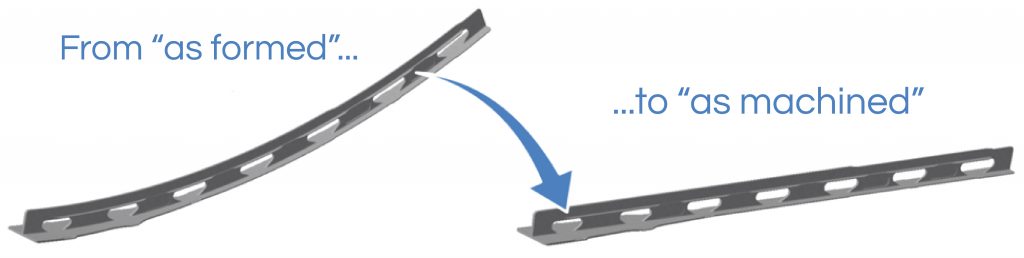

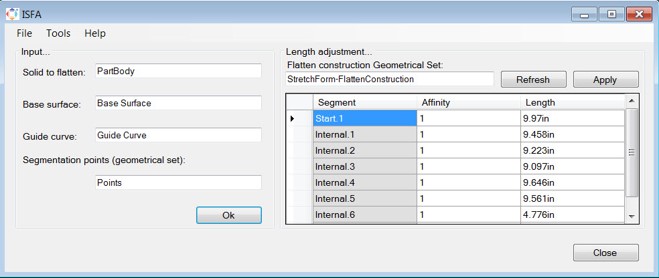

Inceptra Stretch Form Accelerator (SFA) is used in conjunction with CATIA V5 to derive the linear state from formed models of non-uniform cross-section. These types of geometries are common in the Aerospace industry for stringers, straps, and fuselage components. These parts typically go through a manufacturing process called stretch forming or roll forming. One of the requirements of the manufacturing process is an intermediary step to obtain the linear, or extruded, shape. Machining in the linear state, then forming the machined part, is more cost effective than trying to machine the finished product.

This application is of specific benefit to airframe manufacturers who begin the production process with an extrusion or bar stock to create machined-then-formed parts. Capabilities cover a full range of cross-section profiles, including T, L and Z-shaped extrusions. Using the customer-provided 3D CAD model, the Inceptra® SFA quickly and accurately creates the linear form of the part, generating the extruded “as machined” state for manufacturing.

Key Features

- Works in combination with a CATIA V5 session

- Limited user input required

- Works on native CATIA V5 or imported geometry such as STEP or IGES

- Creates the linear “As-Machined” state for NC Programming

- Different cross-sections support, T, L, Z, and others

- Multiple direction forming operations supported

- Varying bend allowances can be defined along the part

Licensing

- CATIA prerequisite of CAT or MD2+KT1

- Generative Surfacing capabilities recommended

- Concurrent License