Unlock Compelling Business Value with Virtual Technology

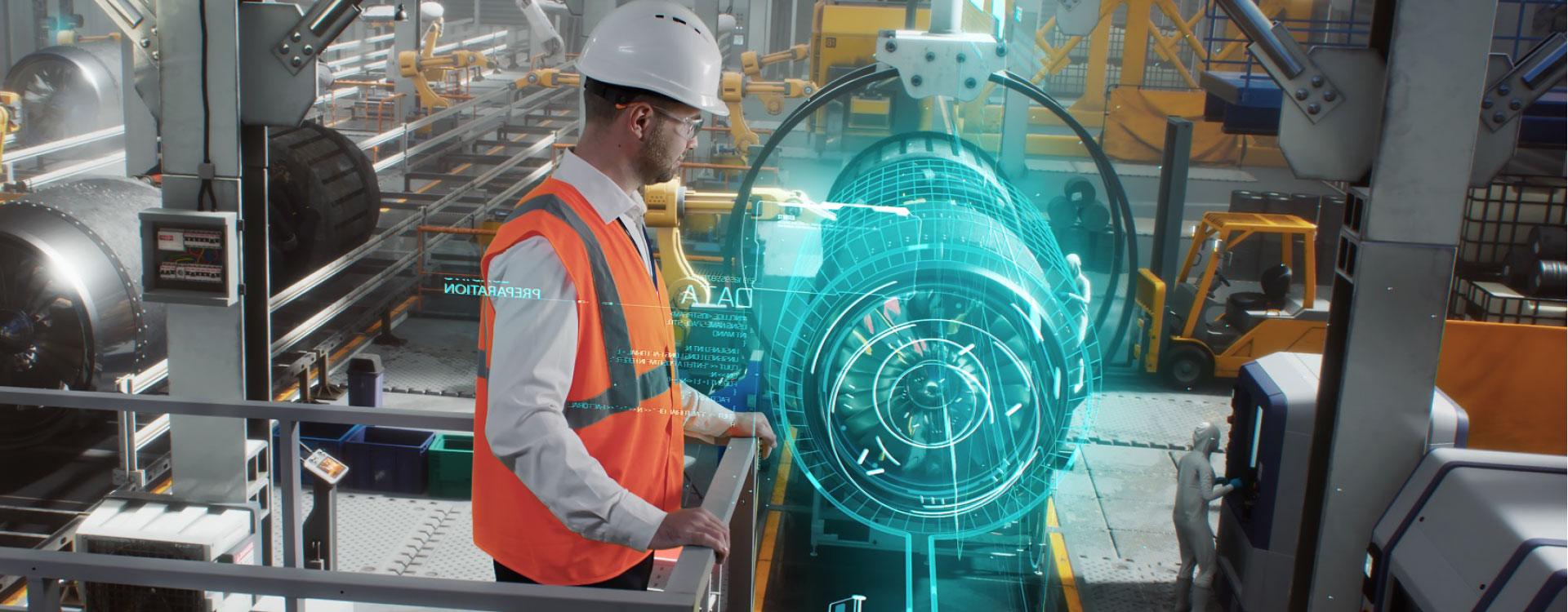

Product success and profitability are impacted when information slips through the cracks with organizational silos. To bridge that gap, top Aerospace & Defense original equipment manufacturers (OEMs) have turned to virtual technology. This technology has allowed them to build more efficiently and therefore accelerate manufacturing engineering productivity.

Businesses manufacturing components for aircraft, ships, spacecraft, weapon systems, and defense equipment need to maximize production capacity without compromising quality. In this report, our partner DELMIA collaborates with Jim Brown, president of Tech-Clarity to explore how the increased use of virtual technology solutions has played a key role in driving top performers in manufacturing.

With virtual technology companies can create significant value in terms of time and cost savings. When companies digitalize processes in manufacturing planning and equipe engineers with capabilities to build and simulate 3D virtual prototypes it’s a win-win for companies.

Based on the survey results detailed in this report, we take an in-depth look at:

- The most important aspects that drive product success and profitability

- Key challenges in process design and manufacturing engineering

- Opportunities to drive improvement for manufacturers

- Potential business value created among top performers

- Recommendations and next steps for manufacturers

Get the full details now by downloading the report.

Enhance Efficiency with Virtual Technology – DELMIA

Tech-Clarity and our partner DELMIA surveyed 177 industry players. The results of the survey found that achieving product development success while meeting evolving demands relies on manufacturing engineering efficiency, driven by digitalization. In other words, Virtual Technology is key to innovation and resilience.

Validating manufacturing processes with 3D and virtual simulation in Aerospace & Defense industry leads to:

Optimizing Aerospace & Defense Manufacturing with Virtual Build