Fluids simulations to improve real-world performance

In the modern competitive world of product innovation, industries demand the complex simulation of their product’s real-world behavior under extreme conditions; such as vehicles wading, powertrain lubrication and critical flight maneuvers.

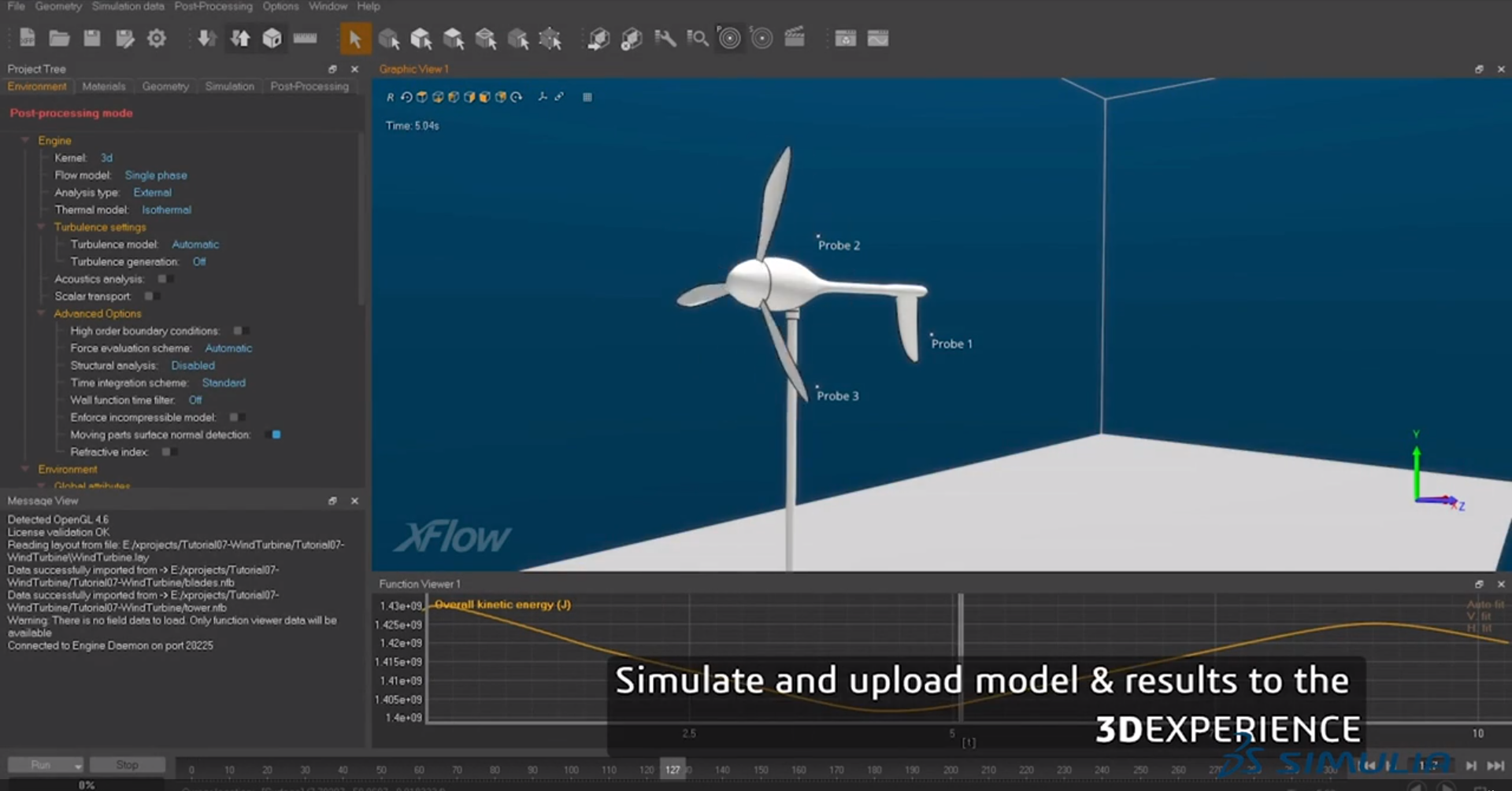

XFlow offers particle-based Lattice-Boltzmann technology for high fidelity Computational Fluid Dynamics (CFD) applications as a part of SIMULIA’s Fluids Simulation portfolio.

The state-of-the-art technology of XFlow enables users to address complex CFD workflows involving high frequency transient simulations with real moving geometries, complex multiphase flows, free surface flows and fluid-structure interactions.

Its automatic lattice generation and adaptive refinement capabilities minimize user inputs thereby reducing time and effort in the meshing and pre-processing phase. This enables engineers to focus the majority of their efforts on design iteration and optimization.

With XFlow’s discretization approach, surface complexity is also not a limiting factor. The underlying lattice can be controlled with a small set of parameters; the lattice is tolerant to the quality of the input geometry and adapts to the presence of moving parts.

Advanced rendering capabilities provide realistic visualization to gain deeper insight into flow and thermal performance. XFlow’s unique capabilities enable companies to reduce physical testing while making to make better design decisions faster.

SIMULIA Fluids Simulation is driven by three complimentary technologies that provide customers with scalable fluids simulation to address broad range of real world applications. Dassault Systèmes SIMULIA brand is committed to enhancing and expanding our Fluids Simulation portfolio to provide end-to-end solutions for broad range of Industry Processes on the 3DEXPERIENCE® platform.