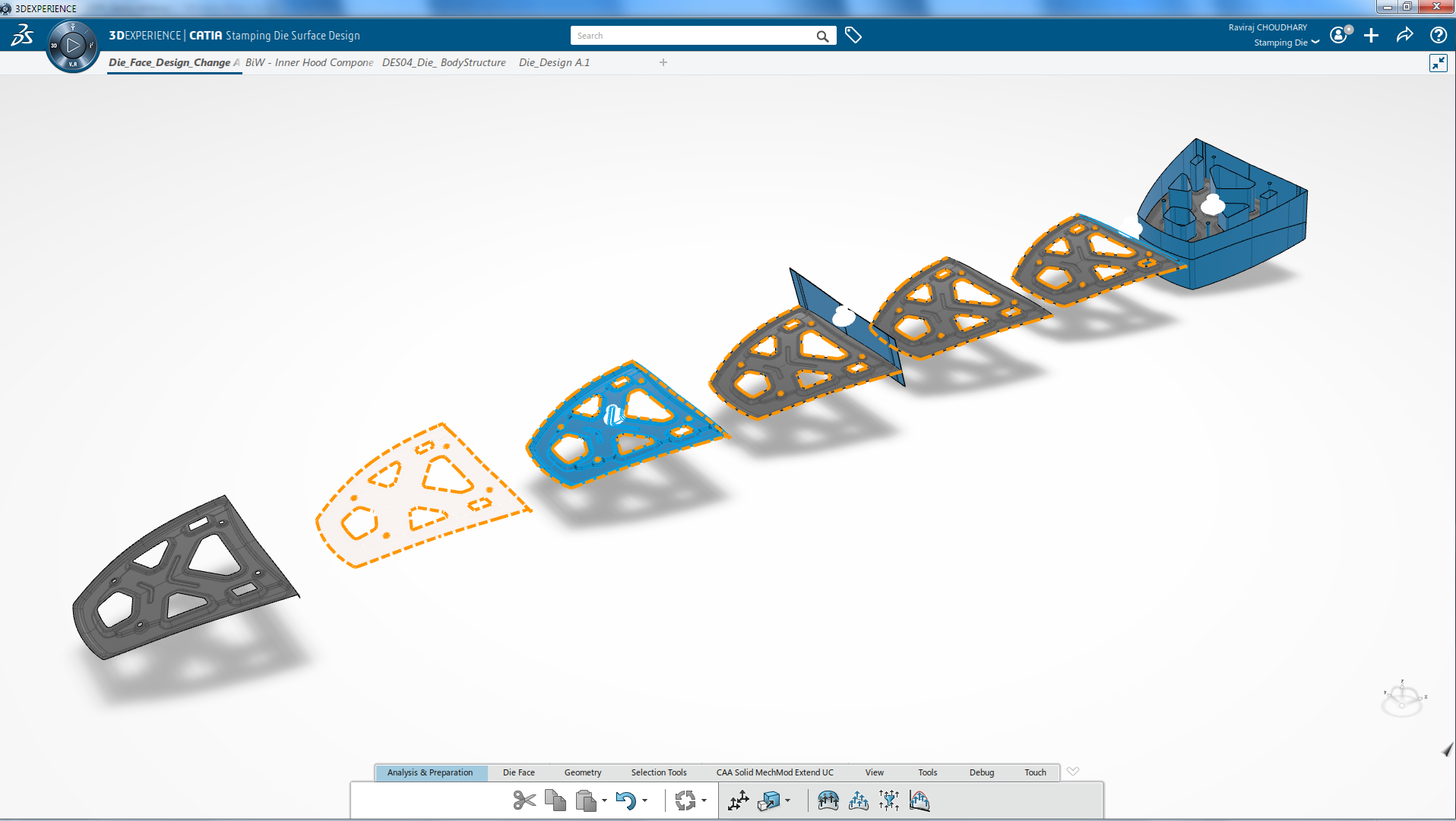

Design for manufacturing of best in class stamping die tool.

Description

CATIA Stamping Die Designer, increases productivity by guiding users from the conceptual planning through to detailed tooling design of complex stamped sheet metal parts.

Early concept method planning allows to anticipate manufacturing constraints and facilitate collaboration between design, tooling and the supply chain organisations. Easy to use specialist features and wizards guide the user in best practices, helping the tool designer work with and extend complex surfaces without having to be a surfacing expert.

The role has a discipline-specific set of functions for the optimization of stamping direction, creation of addenda surfaces, trim lines and spring-back compensation, all with full associativity to the original part geometry. This ensures high quality die geometry and right-first –time tooling.

Key Benefits

- High productivity with specialized wizard and features

- Intuitive and process oriented

- Facilitate design for manufacturing collaboration with early process engineering

- Die face method planning

- Conceptual die surface design to enable quick validation based on simulation

- Simplify and automate the tool compensation process from simulation inputs

- High quality surfaces for manufacturing