Resource Configuration Milling is a new buzz phrase you may have heard, but what is it and what does it mean to you? In this article we will not only explain RCM, but we will take you from the past environments of the shop floor and the programming departments to the present and beyond.

Let’s start by taking a look at machine shops 20 years ago. There was absolutely no organization whatsoever. If there was an open space on the floor they would put a machine there. The same was true with the resources such as: machining fixtures, fixture plates and clamping vises. They were typically just left wherever the last person used them. This resulted in wasted time looking for equipment. Other resources such as cutting tools were just thrown in a box on a shelf that you would have to pick through. Communication between the CNC operator and the programmer was nonexistent.

Obviously this was very inefficient, so companies started to organize by putting all of the machines together, storing the resources in a designated area and keeping cutters inside tool cribs. Departments began communicating, but there were still instances when certain resources were needed but unavailable. The machinist would go to get them off the designated shelf – only to find that they were already set up on another machine. Although more organized systems were in place, companies lost time and money by having to reprogram parts to other available resources.

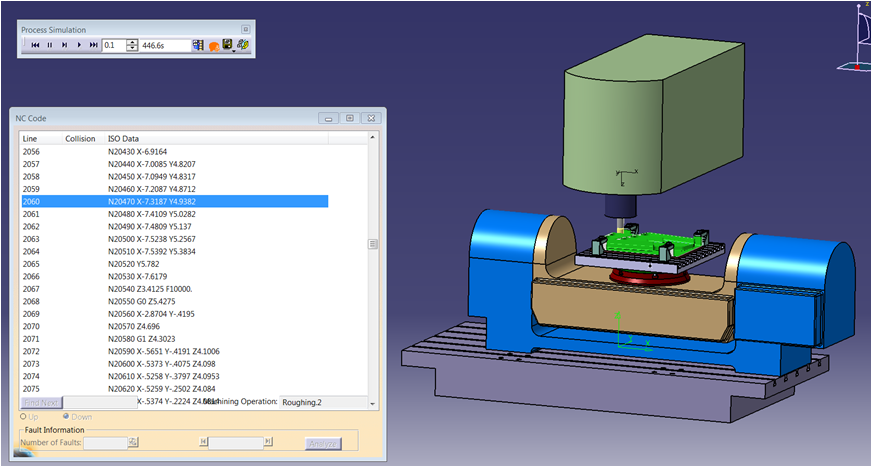

NC programming has also changed over time. 20 years ago there was no solid material removal or iso code verification. Programmers had to stare at the toolpaths intently searching for any type of clearance issues, gouges, or possible crashes. Unfortunately issues were often missed, causing material waste or machine damage.

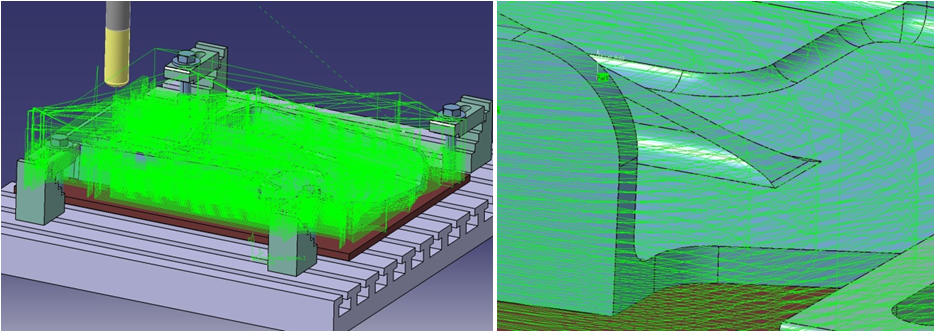

Fast forward to today. In addition to solid removal replay we also have fully integrated iso code simulation directly inside of CATIA. This allows us to see exactly what the machine is going to do before it ever hits the floor and saves companies hundreds of thousands of dollars by catching any inaccuracies up front. Companies everywhere have adopted this method. However there is still one thing missing: machine and resource management.

This brings us to Resource Configuration Milling within the 3D EXPERIENCE platform. It allows you to represent the work cell exactly the way it is on the shop floor. You can now have a predefined machine configuration that can contain not only the machine, but all of the Machining accessories that the work cell out on the shop floor has. Why is this important? Because now programmers have the ability to set up their own machine exactly like the guy on the shop floor would. The visibility that has always been missing is now available. You can see what resources are available and exactly what tools are available for a specific machine. With the 3DEXPERIENCE, the last disconnect between the shop and the programming department is now eliminated.

Resource Configuration Milling within the 3D EXPERIENCE platform ensures the process is done correctly the first time, which ultimately saves companies time and money.

Article compiled courtesy of John Jeffrey

Application Engineer

Inceptra