Business Value of Eliminating Non-Value-Added Work

Today’s market is so competitive; it is hard to stand out. To be successful companies must empower their engineering teams to differentiate products on innovation, quality, performance, and cost. Did you know engineers waste so much time on non-value-added work? They only spend about 51% of their time designing.

Tech-Clarity’s research uncovered some significant engineering inefficiencies that contribute to this including:

- 20% percent of the time, engineers are working with outdated information

- An overwhelming 76% of them say they would like the data to be updated more quickly

- 41% of respondents report it takes a couple of days or more to get the changed information to the entire team

Tech-Clarity’s research consists of a survey of over 220 manufacturers. This research study examines how engineers spend their time, identifies time-consuming activities that waste time, and presents opportunities for improvement. This research is an updated look at a survey of 248 manufacturers conducted in 2014 and examines how trends have evolved over the last several years.

Consider the possibilities when engineers can minimize time-consuming tasks and redirect their energy towards valuable engineering work that drives improved designs. Discover strategies to reduce wasted effort and enhance focus on value-added engineering and innovation work by exploring our eBook.

Complete the form to read Tech-Clarity’s eBook.

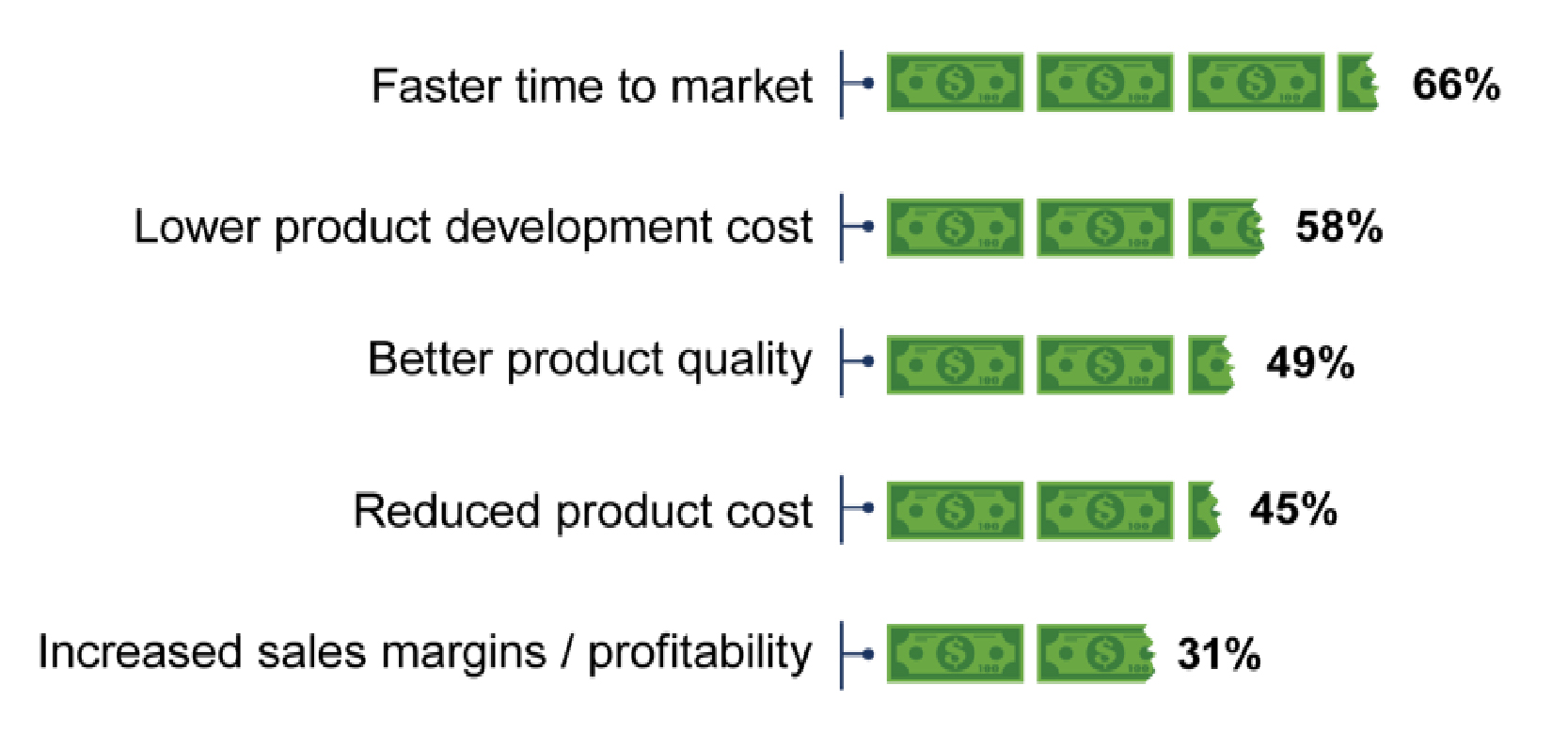

Eliminating Manual Data Management Tasks Creates Business Value

Manufacturers widely acknowledge that eliminating all the manual tasks associated with data management, such as searching for it, checking it in and out, and sharing it, would greatly benefit their companies.

Interestingly, only 2% of survey respondents said there would be no impact on the business. This means an overwhelming 98% of manufacturers see business value in reducing non-value-added work.