PLM with the 3DEXPERIENCE platform

This white paper discusses the role of product lifecycle management (PLM) in addressing product development challenges and why augmenting PLM with a platform approach provides maximum advantage. Companies that connect their entire product development ecosystem or value network can better accelerate innovation and achieve business objectives.

Competition and customer demands drive innovation and operational excellence in aerospace and defense. Companies embrace technology like robotics, automation, IoT, AI, and big data to enhance aircraft development and maintenance. PLM helps manage engineering processes, but it’s insufficient for full optimization. Consequently, to achieve operational synchronization and supply chain integration, it is imperative to connect non-engineering activities to PLM on a unified platform. This linkage promotes collaboration and streamlines processes from concept to the final takeoff.

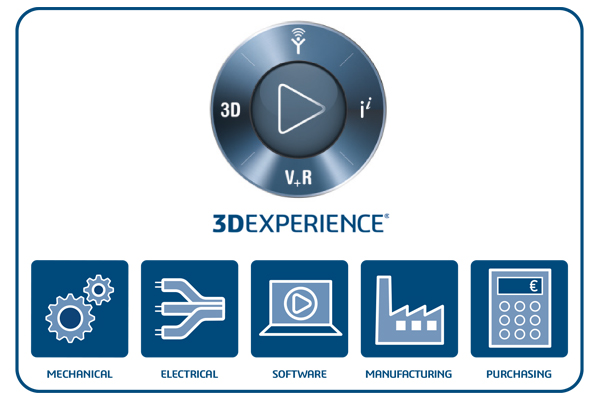

With the 3DEXPERIENCE® platform, an enterprise is digitally connected through data-driven apps working from a single and complete product definition. The platform provides different functional views on the same data, rather than separate data repositories for each function.

PLM Collaboration Services on the 3DEXPERIENCE platform manage designs created with various CAD tools like CATIA V5, 3DEXPERIENCE CATIA, SOLIDWORKS, and third-party solutions. These services ensure widespread accessibility of PLM data across the value network, involving all relevant stakeholders. Design updates are promptly communicated to team members across departments like design, engineering, manufacturing, purchasing, and service and support.

Complete the form to read our white paper.