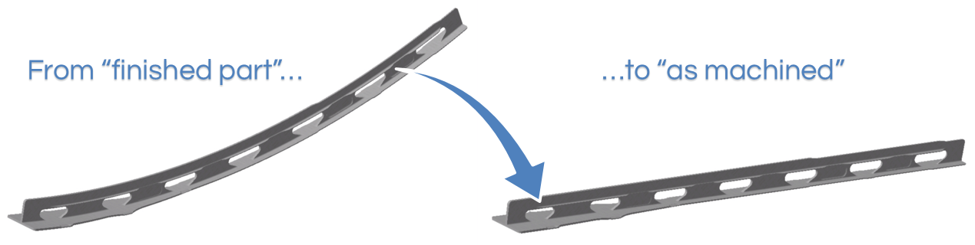

Inceptra is pleased to announce the release of the Inceptra® Stretch-form Flattening Accelerator (ISFA), now available for purchase as an add-on to CATIA V5. This application is of specific benefit to airframe manufacturers who begin the production process with an extrusion or bar stock to create machined-then-formed parts (i.e. straps, stringers, fuselage frame components, etc). Capabilities cover a full range of cross-section profiles, including T, L and Z-shaped extrusions. Using the customer-provided 3D CAD model, the ISFA quickly and accurately “un-forms” the part, generating the extruded “as machined” state for manufacturing.

Many parts being released for production today are engineered in a 3D CAD tool, and as a result those parts are designed in the final 3D state. The challenge for manufacturers is that the finished part is what they deliver, not what they start with. In many cases, the manufacturing operations can be applied to the extruded state of the part and then “formed” into the final shape. Machining in the extruded state is typically less expensive because it reduces the amount of raw material required, allows the use of cheaper machine tools, fewer machine setups, and often eliminates the need for secondary tooling.

Unfortunately, suppliers are typically left to derive the extruded shape from the end design themselves, and in many cases this step of the manufacturing preparation is outsourced to be performed manually, increasing lead time and cost. The Inceptra® Stretch-form Flattening Accelerator (ISFA) allows suppliers to quickly derive the manufacturing model in-house, improving the manufacturing process by providing fast and reliable results. Using the ISFA to develop the proper “as machined” state virtually, can result in significant time and cost savings.

Watch the ISFA in action…

For more information or to request a product demonstration, please send an inquiry to info@Inceptra.com

Article compiled by Jason Curtis

Director of Engineering, Inceptra