In our first segment we discussed three new Enhancements within 3DX NC Manufacturing:

- New operation dedicated to impeller hub machining

- New stiffener operation dedicated to machining tops of ribs

- New concentric milling strategy for hard metals and high speed machining

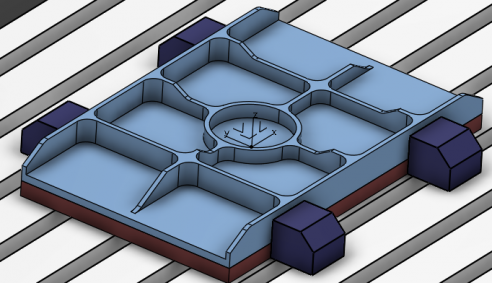

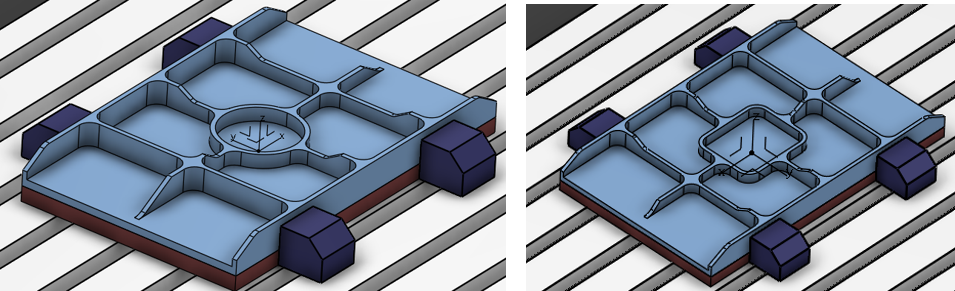

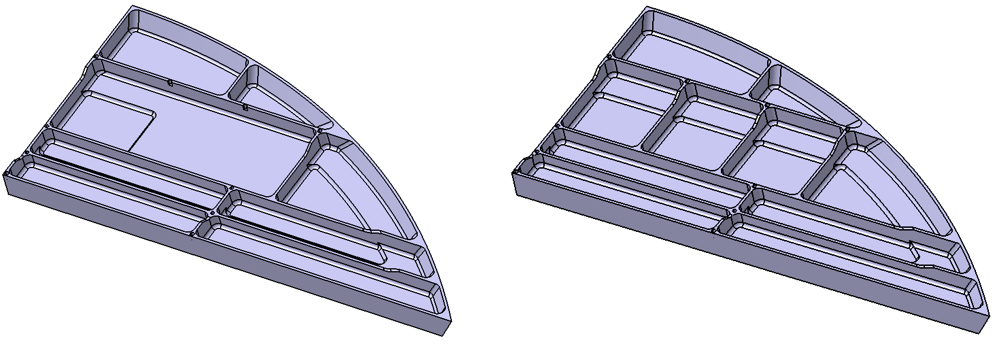

In this edition we will look at new functionality dedicated to machining similar parts or sometimes referred to as a family of parts. In the example below we see the same type of features, although consisting of different shapes.

Here we have similar parts that consist of different shapes and number of features.

However, the tools, specific Machining Operations, and strategies used to program these parts are not so different. Companies hone their knowledge of machining best practices over time and knowing what works best to get the parts off the machine as fast and accurately as possible makes a big difference in profitability. So shouldn’t your programming software make it easier to use that knowledge to program other ‘like’ parts in the same way and be able to do it very quickly? That is exactly what the 3DEXPERIENCE Reuse Programming function brings.

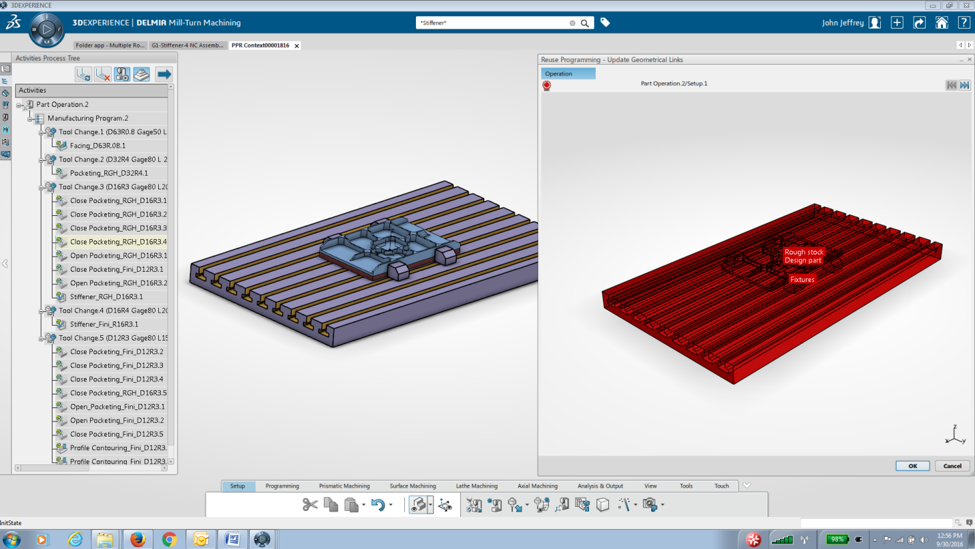

Reuse Programming operation

Reuse programming lets you apply Machining Operations from an existing (completed) machined part.

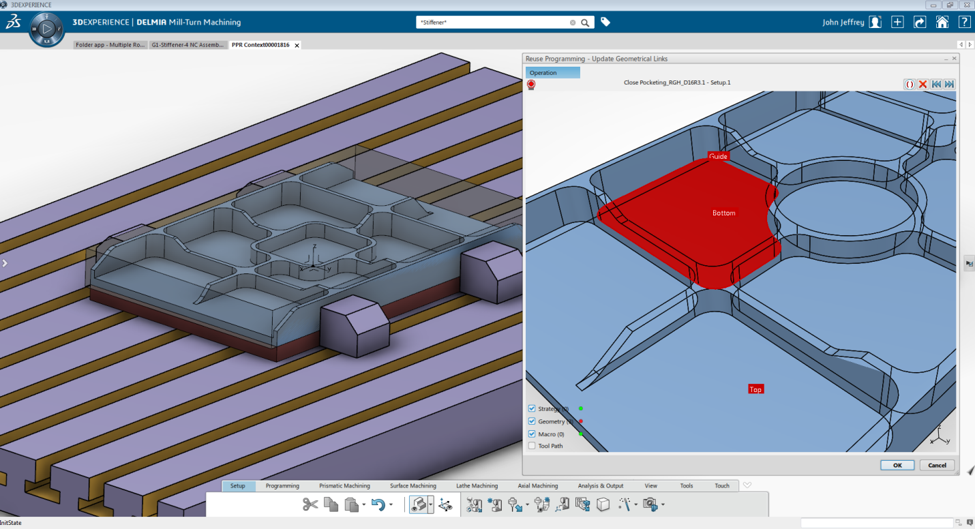

Once a new process is created and we run the Reuse Program, the system prompts us to pick and existing file. Above you can see the part to be machined on the left and the completed part on the right.

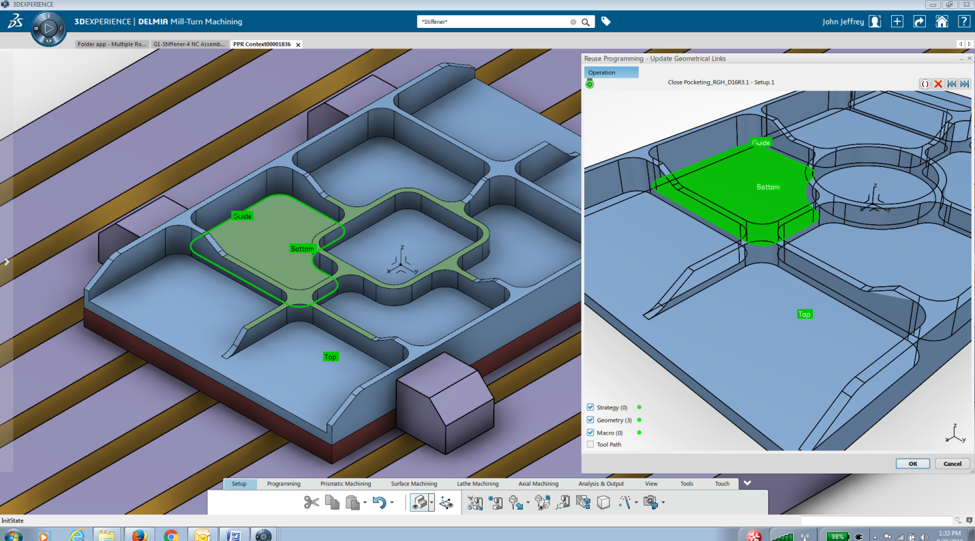

The geometry wizard begins to walk you thru what geometry needs to be selected for that operation. Once all has been fulfilled it turns green and moves on to the next Machining Operation.

To further explain this process and see the final results, below is the link to our youtube video.

Article compiled courtesy of John Jeffrey

Application Engineer

Inceptra