Sharpen Your Competitive Edge with Digital Transformation

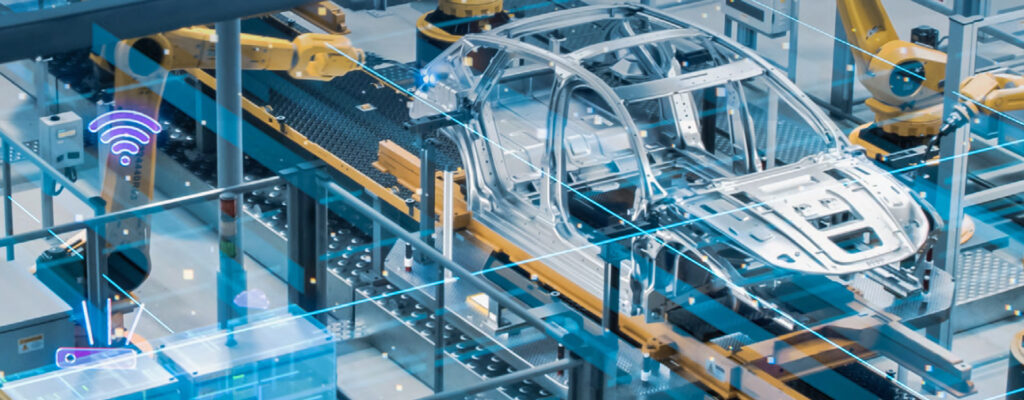

How can automotive manufacturing maintain cost-efficiency while striving to achieve their transformation goals in the competitive field of electric vehicles (EV) and battery production? The transportation and mobility industry is witnessing a race among manufacturers to outdo one another in terms of innovation. Additionally, customers are increasingly demanding higher-quality and personalized products delivered at a faster pace.

DELMIA’s integrated solution targets a crucial gap in the value chain: the disconnect between production and warehouse management. By implementing DELMIA, a digital thread is established, enhancing inbound material flows, line-supply, and outbound material flows. This solution effectively coordinates production orders and manufacturing bills of material with inventory management within plants and throughout the supply chain, encompassing:

- Work in Process (WIP)

- Raw materials

- Purchased parts from suppliers warehoused on-site or off-site

- Semi-finished inventory residing at a feeder production line or work cell

In order to emerge as an industry leader, automotive manufacturers can utilize DELMIA’s integrated solution to connect material flows throughout the supply chain. By doing so, they can gain real-time control and visibility, enabling them to drive operational efficiency and foster sustainable innovation.

Complete the form to download our eBook.

Discover More

Material Synchronization for Automotive Manufacturers | DELMIA

Learn how to close the gap between warehouse and production with DELMIA’s integrated Material Synchronization solution. Discover how automotive manufacturers can use it to gain real-time control and visibility across your supply chain to drive operational efficiency and sustainable innovation.

Article

Autoliv

Learn how DELMIA Apriso maximizes production, quality, and maintenance for Autoliv to uphold their consumer’s health and safety in automotive to a higher standard.