A Simulation Role for Analysts who specialize in the creation and/or management of large and complex finite element assemblies requiring automated modeling techniques and the collaborative efforts of several engineering teams

DESCRIPTION

Finite Element Modeling and Assembly Specialist specializes in the creation and/or management of large and complex finite element assemblies requiring automated modeling techniques and the collaborative efforts of several engineering teams.

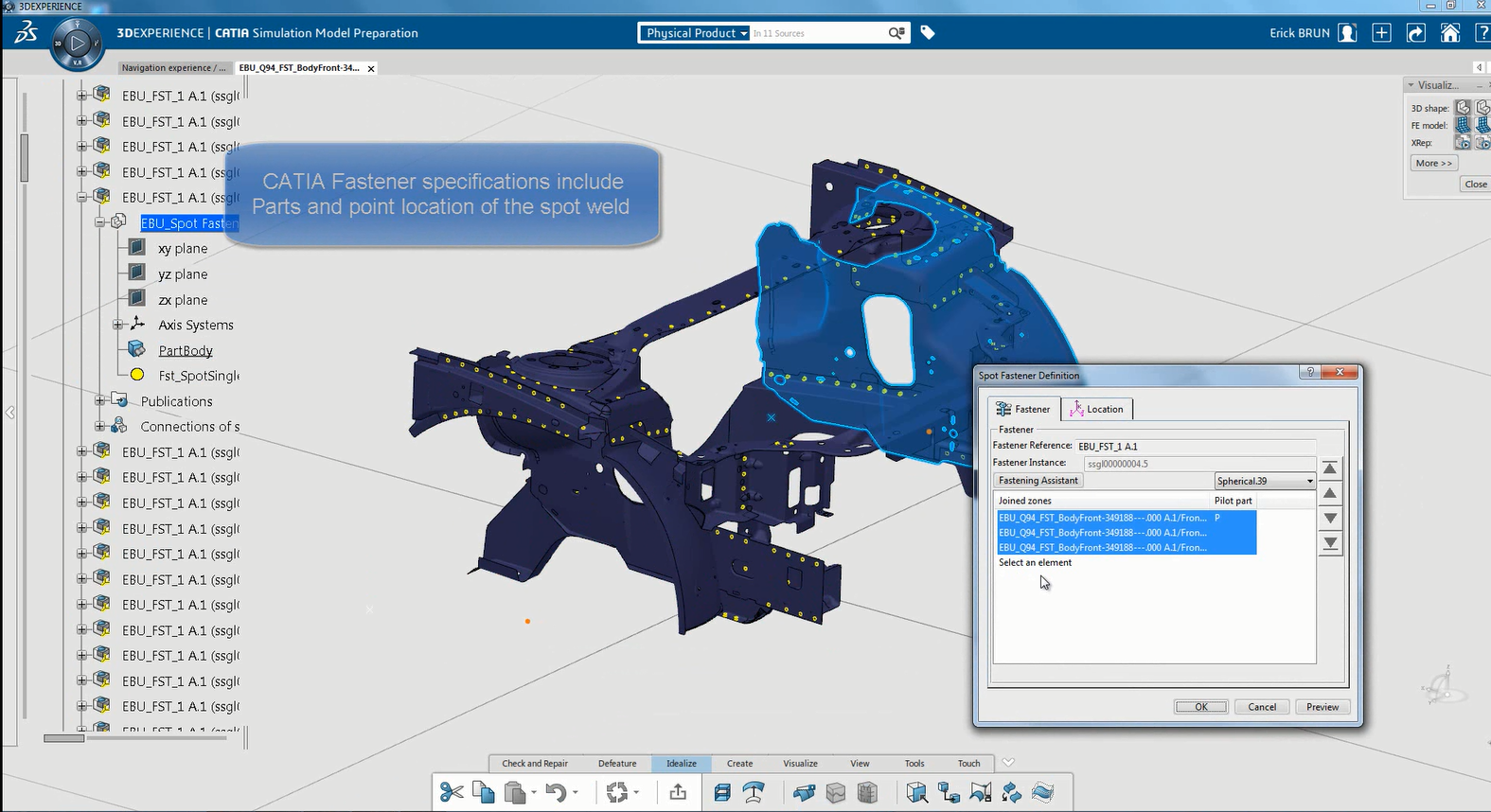

The toolset enables the user to easily create Finite Element models for small or large assemblies, or import them from 3rd party tools, and manage them on the 3DEXPERIENCE® Platform. Finite Element model representations can be created based on predefined rules, including geometry idealization, high quality meshing and creation of sections and other abstractions (masses…). The meshes can be checked and edited using state-of-the-art meshing tools and then the model itself can be checked and assembled using a wide variety of predefined connections.

Finite Element Modeling Specialist allows Specialist users to define procedures through a scripting language, thus capturing the company’s modeling standards and best-practices, which can be shared with other users across the enterprise on the 3DEXPERIENCE Platform.

Benefits:

- Collaborative tool to build large-scale, multi-level assemblies leveraging multiple teams and locations

- Provide Product Development, Mechanical, Design, and Simulation Engineers the expert tools needed to prepare advanced simulations.

- Automatic generation of high quality simulation models via ‘fire and forget’ execution on HPC

- Less time spent looking for geometry, part assembly information, fastener data, etc. thanks to the collaborative nature of 3DEXPERIENCE.